Ferro purlin S-Horizontal Sodales Sodales, quod Support tecto et Wall Cladending in Industrial, Commercial et Residential Textus, sunt critica ad onus distribution et structural stabilitatem. Tamen, in nuditate humorem, UV radialis, industriae chemicals et temperatus fluctus facit corrosio periculum. Secundum ad MMXXIV Nace International Study, corrosio costs in global constructione industria an æstimatum $ 2.5 trillion annuatim, cum ferro structuris ratio ad XL% illius totalis. Nam ferro, quae saepe expositae dura environments, lectio effective longa-term anti-corrosio modi est essentialis ad obscuratis postea costs et ensuring structural integritas. Infra est testimonio-fundatur dux ad maxime fideles consilia, fundatur in industria signa et ipsum optimum exercitia.

I. Material Electio: ROSIO-RISTINUS Steel Alloys

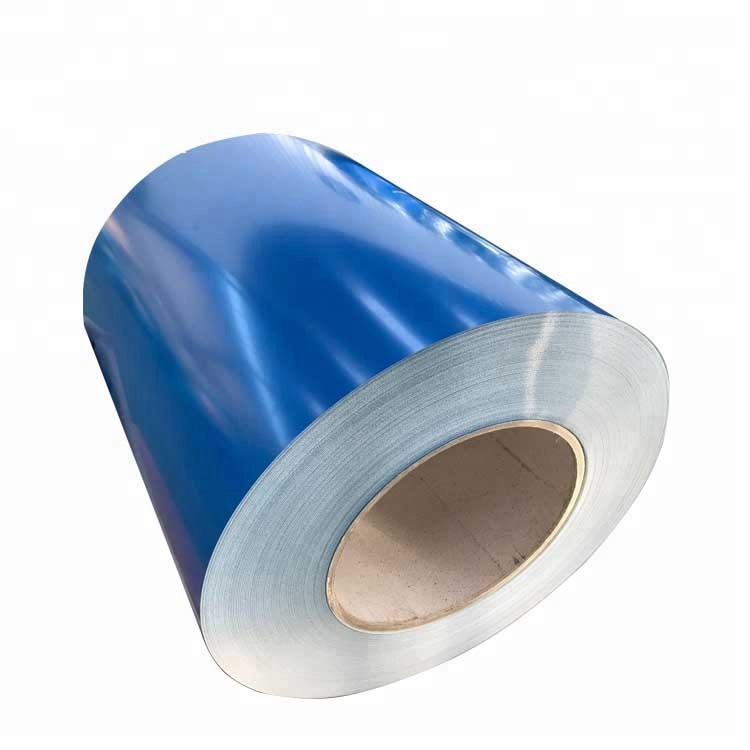

Fundamenta diu terminus corrosio praesidio incipit cum eligens ius ferro. High-vires humilis-Alloy (Hsla) Steels -Engineered cum additionibus aeris, Chromium, Nickel, et phosphoro-formam tenuis, adherent Passive cadmiae layer super superficiem. Hoc iacuit acts ut obice ad oxygeni et humorem, tarditatem corrosio per tempus.

Key Alloys et Signa:

- ASTM A588 (Weathering Weather) : Habet 0.20-0.30% aeris, quae accelerat passiva layer formationem. Specimen pro velit Purlins in rusticus vel urbana ambitus, ubi eius corrosio rate decrescit ab 50-70% post passivam accumsan maturare (typically 1-3 annis).

- ASTM A709 (Steel pontem) : Includes Chromium et Nickel enim amplificata resistentia ad sal imbre et industriae vapores. Communiter in maritimum vel industriae occasus.

Limitations:

Nigrantis ferro est inconveniens pro locis cum stantes aqua aut alta sal concentratione (E.G., maritimae zonis cum frequentant nebula), ut passiva accumsan non formare uniformiter. Nam tales ambitus additional tutela coatings commendantur.

II. Protective coatings: physica et sacrificia claustra

Societates sunt maxime late solebat anti-corrosio methodo ad ferro purlins, offering a statera ex diuturnitatem, cost-efficaciam, et versatility. Tria prima genera dominari industriae applications:

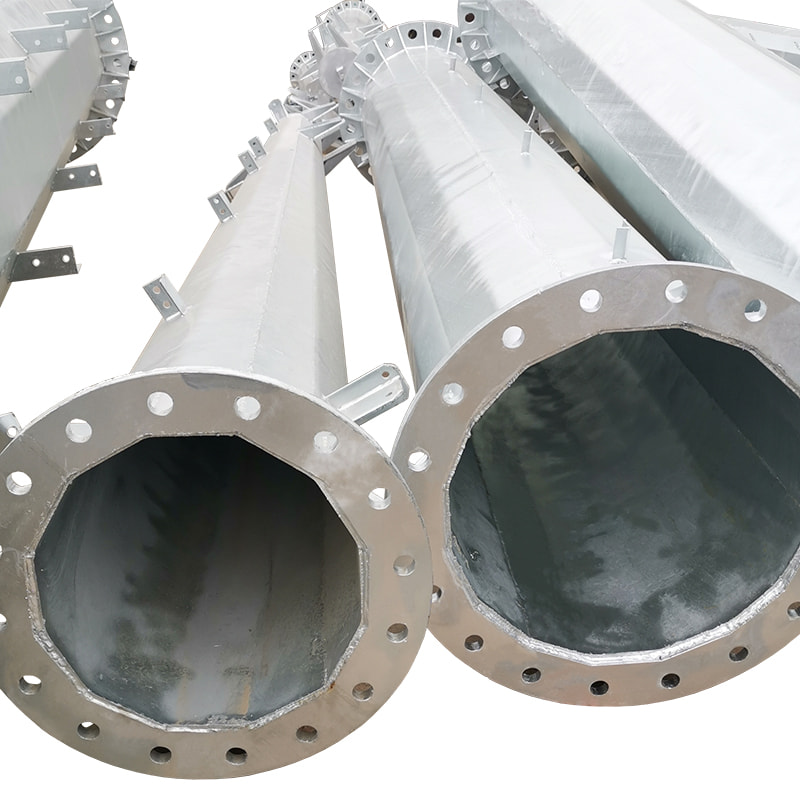

A. Hot, intinge galvanizing (HDG)

Processususususus : Defined ASTM A123 , HDG involves immersing mundum, CONDITANEUS ferro Purlins in Flere (CDL ° C). Et Zinc Reacts cum ferro ad formare metallurgically bonded coating (1.5-2.5 mills / 38-63 microns densissima). Praesidium mechanism : Dual defensionem, cadmiae acts ut a physica obice et providet TRANSMONIUM (Corroding preferentially ad ferro). Performatio : De Galvanizers Association Renuntiationes A L-Anno Service Vita in Rustica areas et 20-30 annis in maritimum environments (cum propriis sustentationem). Minor scalpit sui-sana ut cadmiae ocidizes ad formare tutela cadmiae carbonate layer. Limitations : Susceptibiles ad dampnum a gravibus confligant; exigit pre-treatment (E.G .: Acidum Pickling) ut remove molendini scale.

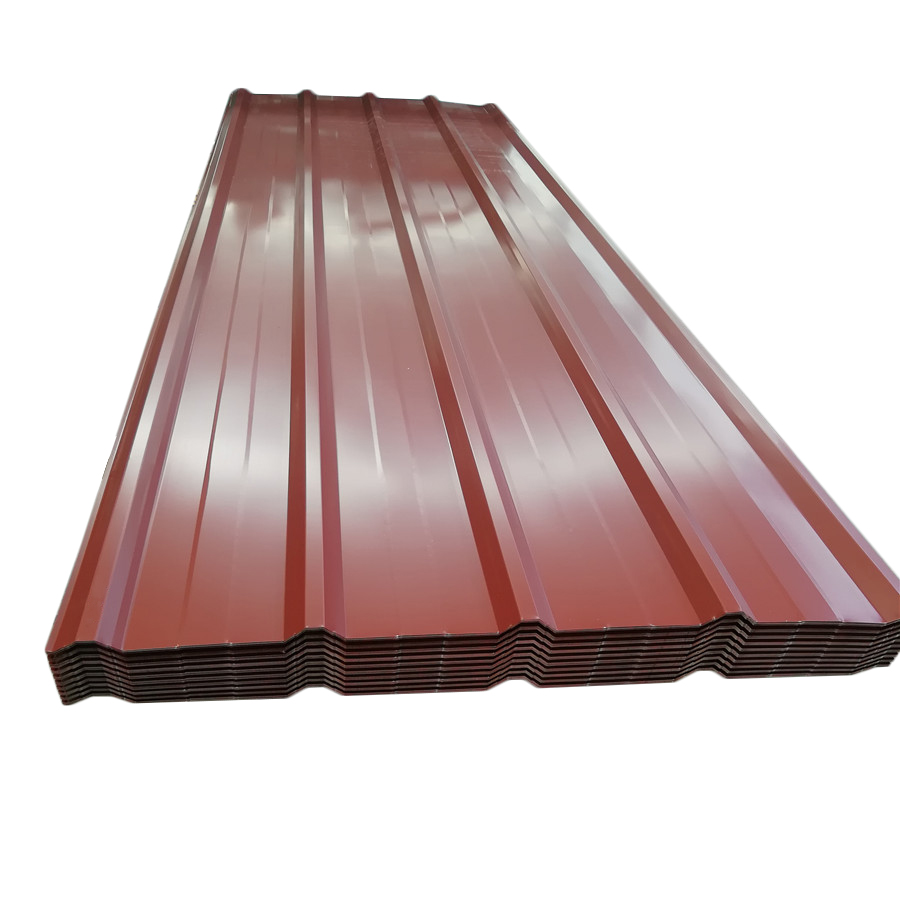

b. Pulveris coating

Process : Gubernari a ASTM D7091 , Electrostatically Crimen Thermosetting Polymers (Polyester, epoxy) sunt sprayed onto pre-tractata (sandblasted) Curatus et in clibano (160-200 ° C). Praesidium mechanism : Forms a densissima (2-4 mills), uniformis coating cum optimum adhaesionem et UV resistance. Performatio : Specimen pro expositae Purlins in Apricus Climates-probat per Europae Coil Coating Association Show nulla significant Degradation post X annos UV nuditate. Voc, libero, aligning cum LEED et Breeam signa. Limitations : String marginibus aut universa geometries ut requirere additional coating; Superficiem praeparatio est critica ad ne delamination.

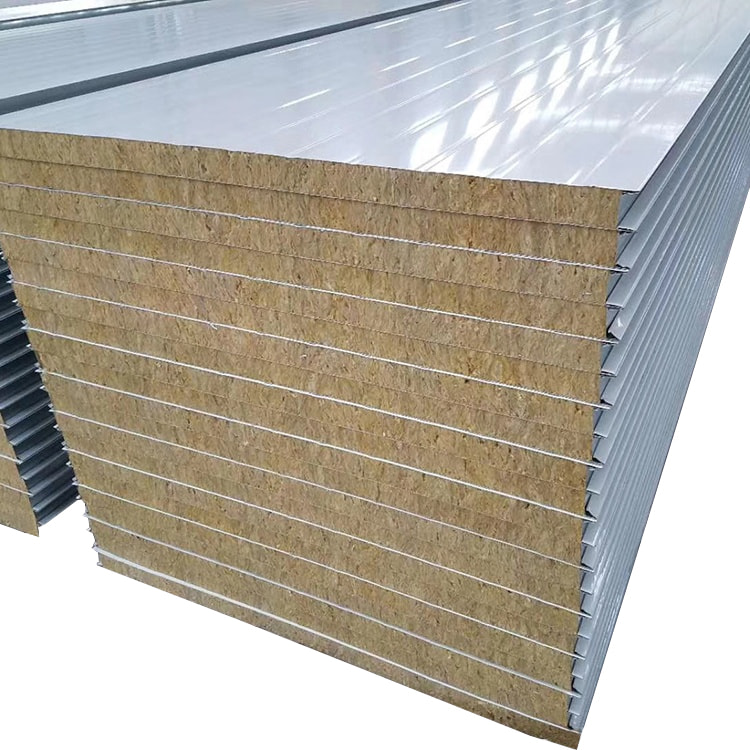

c. Epoxy coatings

Process : Duo-component systems (resin hardener) applicari per imbre aut penicillo. Sanitatum ad lenta, eget, repugnans film. Praesidium mechanism : Cuneos nuditate acida, alkalis, et solvents-communi in Industrial occasus (E.G .: eget plantis, wastewater facilities). Performatio : ASTM D3359 (adhaesionem testing) rates epoxy coatings ut "optimum" pro industriae environments. A topcoat (E.G., Polyurethane) requiritur ad UV resistance. Limitations : Potest creta aut flavo per tempus sine topcoat; Non commendatur ad velit usus sine additional praesidium.

d. Duplex coating (combination)

Nam extrema environments (E.G., maritimum industriae zonas) Duplex coating -Combining HDG cum pulveris aut epoxy topcoat, offert superior praesidium. Et cadmiae accumsan providet hostiam defensionem, cum topcoat adiungit UV et eget resistentia. Studies Show Duplex coatings extend Service Vita per L% comparari unum coatings.

III. Corrosio inhibitors: Chemical Donec

Corrosio inhibitors sunt componit quod forma a tutela amet in ferro superficie, claudebant electrochemical reactiones. Sunt saepe in conjunction cum coatings ad amplificata praesidio.

Genera et Applications:

- Organicum inhibitors (E.G .: Amine-fundatur) additum ad primers vel refrigerationem systems. Efficens enim inclusum spatia (E.G .: CELLA Attici) ubi humorem accumulat.

- Inanic inhibitors (E.G .: Chromates): Cum commune, sed restringitur debitum ad toxicity (Rohs, semoto).

- Testis signa : ASTM d1384 (Aestimatio de inhibitor efficacia).

Beneficia:

- Sumptus-effective existentium structuris (E.G .: Tactus-UPS).

- Compatible cum maxime coatings.

Limitations:

- Requirere iusto reapplicationem (omnis 1-3 annis).

- Inefficax in altus contaminari environments (E.G., grave oleum nuditate).

IV. Cathodic (CP): ElectroChemical Defensionis

Cathodic praesidio supprescit corrosio per ferro purlin in cathode in galvanica cellula. Est praesertim propter buried vel demergi purlins (E.G., in Industrial obterere, marine structurae).

A. Anodes

Process : Adjunctas cadmiae aut aluminium anodes ad purlin. Anode Corrodia pro ferro. Signa : Nace SP0100 (consilio guidelines). Performatio : Specimen pro parva structurae (E.G .: Utilitas polies). Anodes novissimis 5-10 annis ante replacement.

b. Impressa current CP

Process : Usus est externum vim fons (rectifier) ut libera a tutela current ad purlin. Signa : Nace SP0100 (consilio et sustentationem). Performatio : Structures idoneam ad magnum vel complexu (E.G .: Offshore Platforms). Monitored per remotis sensoriis (IOT) ad curare current output.

Beneficia:

- Valde effective ad corrosivum environments (E.G .: Saltwater, acidic terrae).

- Sequitur ministerium vitae a 20-30 annis.

Limitations:

- Monitoring requirit ongoing (Anode perficientur, current output).

- Superiore initial sumptus quam Anodes.

V. Praecaventur sustentationem: Tractus Service Vita

Non anti-corrosio ratio est permanens, iusto sustentationem est critica ad maximizing diuturnitatem. ISO (XII) CMXLIV (Corrosion praesidio de ferro structurae) praebet compage pro sustentationem fundatur in Corrosion Category (E.G .: C3 pro Urbana areas, C5 pro Industrial sapien).

Key exercitia:

- Inspectiones : Visual checks pro coating damnum (E.G .: Lenger, chipping) omnis 6-12 mensibus. Ultrasonic temptationis (ASTM E165) ut metiretur murum crassitudine damnum.

- Tange-ups : Repair minor coating damnum cum compatible depingit (E.G .: Zinc-Rich primario in HDG).

- Emundatio : Remove obstantia (folia, pulvis), quod pedicas humorem-usu humilis-pressura aqua vel mollis penicillo.

- Environmental magna : Install humiditas sensoriis in inclusum spatia (E.G .: Attici) ad deprehendere humorem buildup.

VI. Environmental Mitigation, reducendo nuditate

Designing in environment circa Purlins est sumptus-effective via ad tardus corrosio:

- Drainage : Install gutters, downspouts et fastigio tecto ne staram aqua.

- Evacuatio : Usus Ridge Venti aut Soffit Vents ad redigendum humiditas in Attici (target

- Barriers : Nam eget plantis, uti plastic coatings vel concretum annonamque ad obstructionum nuditate ad corrosit vapores.

- Vapor claustra : Install in tecto systems ad ne humorem penetrationem ad purlins.

Conclusio: Integrated Strategies pro Long-term Donec

Protegens ferro purlins diu terminus requirit a Tailored, Integrated Aditus -Combining materia lectio, coatings, inhibitors, cathodic tutela et sustentacionem. Quisque modum habet vires et limitations:

- HDG : Optimus ad velit Purlins in rusticus / maritimum areas.

- Pulveris coating : Specimen ad serenum, humilis-eget ambitum.

- Epoxy : Critica ad Industrial Occasus cum eget nuditate.

- CP : Necesse est sepelierunt / demergi purlins.

Per aligning his strategies cum Purlin scriptor environment (E.G., maritimum vs. Industrial) et sequenti industria signa (ASTM, Nace, ISO), et redemptores potest, ut fusa, in plenitudine. Sicut sustineri fit a prioritas, innovations sicut bio-fundatur coatings et iot vigilantia systems emergentes ad augendae diuturnitatem dum reducing environmental impulsum.