Ut constructione industria persequitur princeps efficientiam et humilis ipsum, modularis consilio fit unum de core technologiae in agro ferro structuram ipsum. Per innovative ideas de standardization et prefabrication, significantly simplifies installation processus of Steel columnas et trabes , Providemus novum solution ad constructione efficientiam et pretium.

De Essentia Modular Design: a "on-site ecclesiam" ad "plug et ludere"

In traditional steel structure construction, the installation of Steel Columns and Beams depends on on-site cutting, welding and debugging, which is not only time-consuming and labor-intensive, but also easily affected by factors such as weather and manpower. Modular Design Reconstructs hoc processus per hoc core logica:

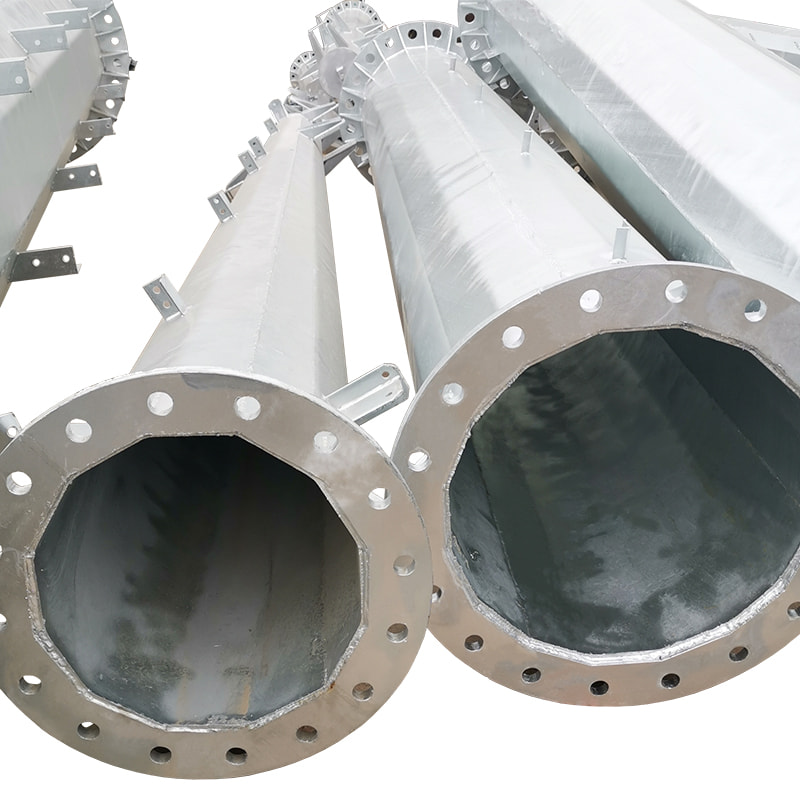

Factory prefabrication et praecisione imperium ferro columnas, ferro trabes et alias components sunt de mensuris in fabrica. Cum auxilio CNC Machina Tools et Bim (aedificationem notitia modeling) technology, dimensional errorem est ut minus quam II mm, quod est multo altior quam in-site dispensando accurate.

Nodi nexu ratio optimization modularis consilio pre-sets fulmine foramina, foramina aut welding interfaces, ut components potest convenienter cito in "Lego-style" modo in site. Exempli gratia, a summus surge project in Civitatibus Foederatis Americae utitur ferro trabes cum pre-installed finem laminis, quod breves installation tempore unius trabem a LX%.

Redigendum in-site processus et manpower dependentia secundum statistics, modularis ferro structuram projects potest reducere LXX% of summus altitudo welding operationes. Operarios tantum opus et obstringere secundum drawings perficere principalis constructione, magna reducendo salute metus.

Data-pulsus efficientiam saltibus

A casu analysis a ARUP, a mundo-clarior Engineering Consulting Company, ostendit quod ad ferro structuram projects usura modularis consilio, in installation ex XL%, et altiore sumptus est a mediocris de XL% et altiore sumptus reducitur a XXV%. Taking a commercial universa in Singapore ut exemplum, eius ferro frame installation cycle est compressa ex XII weeks in traditional exemplar ad VII weeks, et pars exiguo rate reducitur de VIII% ad 1.5%.

Sustainability et industria spes

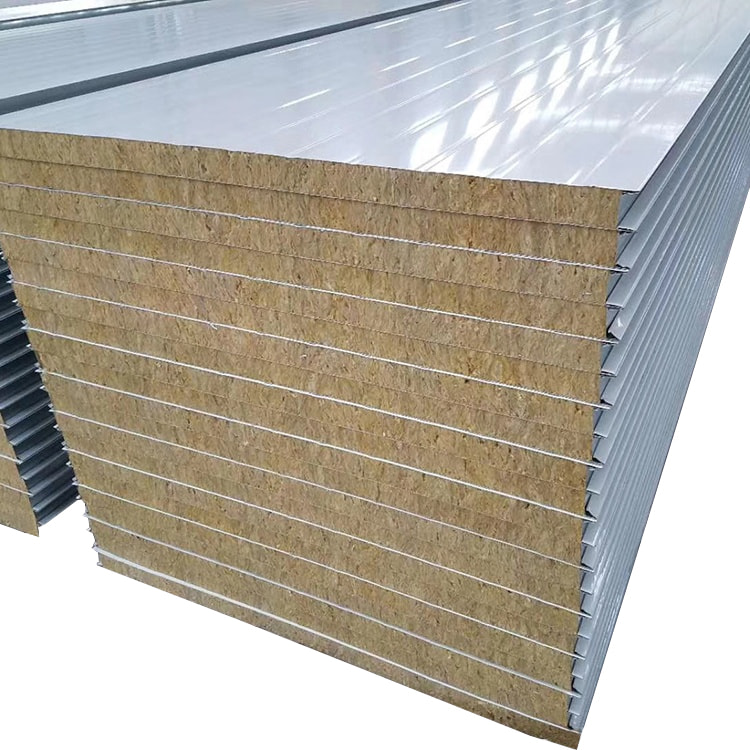

Modular Design non solum amplio efficientiam, sed etiam penitus aptat conceptum viridi tecta. Prefabricated components potest reducere in-site vastum et industria consummatio, cum standardized ferro columnas et trabes sunt facillimus ut disassemble et recycle in futurum. Secundum ad forum Research futurum, in ferro structuram modular aedificium foro erit crescere ad compositis annuis incrementum rate of 6.8% a MMXXIII ad MMXXXX, becoming in amet electionis et civili et becoming in amet elit et civili aedificia.

Challenges et respondeo

Quamvis eius significant commoda, modularis consilio necessitates vincere dolor puncta translationem angustiis et excelsum initial investment. In responsio, in industria est continue optimizing solutiones per split moduli consilio (disassembling magna ferro trabes in transportable unitates) et digital collaboration platforms (integrata et digital collaboration platforms (integrata et digital collaboration platforms (integrata tota processus of consilio, et constructione) .